(This report is provided by Dr. Shu-Fen Hu’s research team in the Department of Physics)

Conventional white LED lighting mainly uses blue LED chips with yellow phosphors to produce white light. However, because its spectrum coverage is not complete, the color rendering of white light by this method is not good; color rendering is a measure that describes the ability of a light source to render the color of a real object. The higher the color rendering of a light source, the closer its color performance is to an ideal light source or natural light. Therefore, the research team used different sintering methods to synthesize high-intensity infrared phosphors with wide emission peaks, established a mechanism to regulate wavelengths, mixed different ratios of high-intensity infrared phosphors, and developed high-intensity infrared LED devices suitable for detector measurements. The high color rendering and high stability of the phosphor will be applied in the LED industry.

(https://doi.org/10.1021/ja304754b)

Human lighting tools have undergone numerous reforms, from more primitive lamps such as torches, kerosene lamps, and candles to incandescent lamps, fluorescent lamps, and light-emitting diode lamps that require electrical conversion, illustrating the changing needs of humans for lighting. During the second industrial revolution, people were familiar with how to use electricity and how to use it as a source of power. Thomas Alva Edison used it as a power source after many attempts using different heat-resistant materials. In 1880, it was found that carbonized bamboo filaments as filament materials could generate a significant amount of light and heat, and incandescent lamps could illuminate for 1,200 hours, leading mankind to enter the era of electric lighting. However, the incandescent lamp converts too much electrical energy into heat energy and only less than 10% of energy into light energy, so fluorescent lamps with higher efficiency were developed. The glass tube contains inert gas and low-pressure mercury vapor, and by increasing the voltage, the filament releases electrons, and the electron-excited mercury emits 253 nm and 185 nm ultraviolet light. Fluorescent powder coated in the wall of the tube emits visible light by absorbing ultraviolet light, but its disadvantages are mercury pollution, large size, poor color rendering, and flash frequency, which prompted the pursuit of better lighting tools, such as light-emitting diodes (LEDs).

At present, the mainstream of commercial white LEDs is to generate white light by mixing phosphor with a single chip, which is called phosphor-converted LED (pc-LED). It can also be divided into UV chips or blue chips. UV chips are often used with blue, green, and red fluorescent powder for better color rendering. However, UV chips are too powerful and can easily damage the epoxy resin of the packaging material, and there are also concerns about the problem of UV light escape. Therefore, after the development of high-efficiency blue wafers, they have become the mainstream of single-crystal type diodes. For example, in 1997, Nichia Chemical applied for a white light patent, US 5,998,925, for the excitation of a yellow fluorescent powder (Y3Al5O12:Ce3+; where YAG is the main lattice and Ce3+ is the luminescence center) by means of an indium gallium nitride (InGaN) diode. Subsequently, various green and red phosphors were developed to meet the needs of various fields to improve color rendering and increase the color gamut.

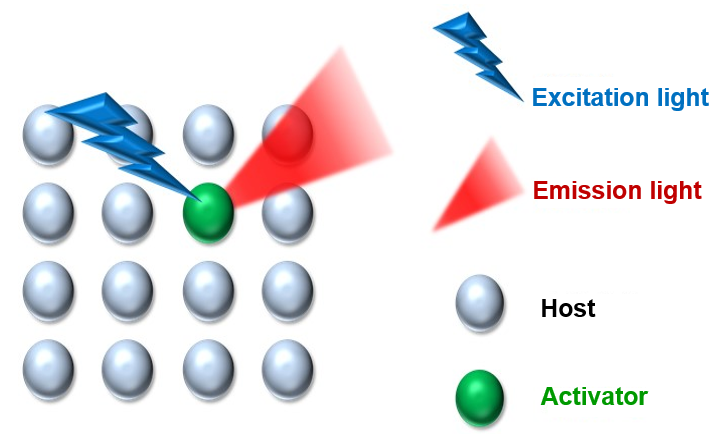

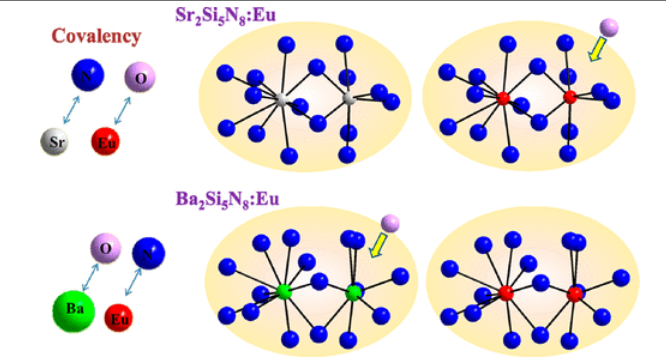

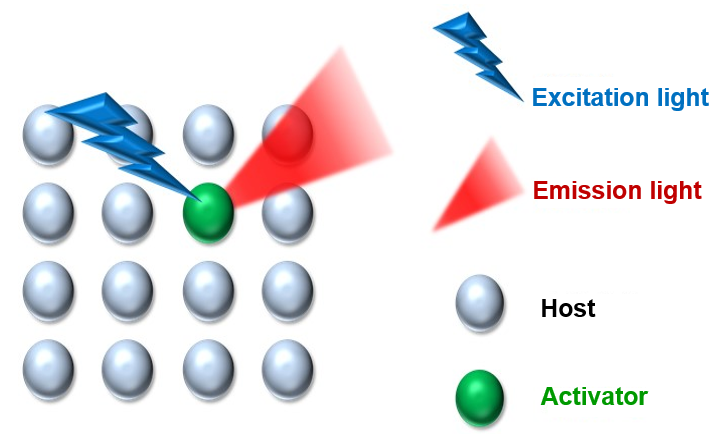

A phosphor is a substance that produces a cold luminescence phenomenon and is mainly composed of a host lattice and an activator. As shown in Figure 1, the activator is the emitting center and is mixed into the host lattice in small amounts. The emitting characteristics of the activator are determined by the coordination environment of the host lattice, and some of the phosphors are mixed with a trace amount of sensitizer, and the energy of the excitation source is transferred from the sensitizer to the activator by energy transfer to enhance the light emitting efficiency.

Figure 1. The main structure of the phosphor and the activation center is illustrated.

Prof. Shu-Fen Hu has established a complete laboratory for the synthesis and characterization of fluorescent powder in the past decade or so. The instruments and analytical methods used in the laboratory are shown in Figure 2.

Figure 2. The diagram of the equipment and analytical methods of the phosphor characterization laboratory was established by Prof. Shu-Fen Hu.

Due to the advancement of human-computer programs and technology, artificial intelligence is developing rapidly and is used in many fields such as medicine, mathematics, and neurology. Infrared LEDs are an eye-catching development that has been used in many fields such as health inspection, iris recognition, and food safety, as their accuracy and brightness have increased dramatically. In the early days, if we wanted to analyze basic information about the body such as glucose concentration and blood oxygen level, we had to use large instruments with high precision or even invasive measurements. However, in recent years, we have been able to use infrared irradiation to detect the concentration of substances to be measured by the magnitude of absorption values at different wavelengths, significantly reducing the measurement threshold, measurement time, and cost. However, conventional infrared LEDs are limited by their narrow half-height, and the information provided by a single LED is limited. For measuring multiple messages, multiple infrared LED devices are required. However, this will make the device much more costly and difficult to miniaturize, and the circuit design is more complex, limiting the application. Therefore, the best solution to this problem is to develop a device that uses a single LED chip to excite infrared phosphors. This method of infrared LED can significantly reduce the size of the device, lower the cost and reduce the circuit control design.

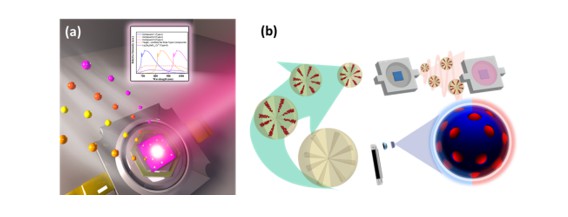

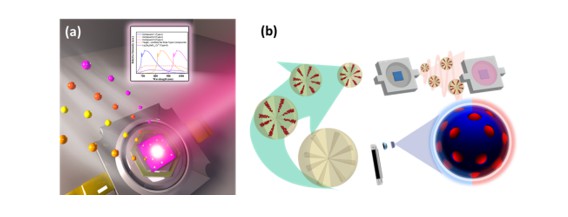

In recent years, Prof. Shu-Fen Hu has led her team to synthesize high-intensity infrared phosphors with wide emission peaks by using different sintering methods, analyze their structures and emission characteristics, regulate their emission wavelengths, and establish a wavelength control mechanism to mix different ratios of high-intensity infrared phosphors to develop high-intensity infrared LED devices suitable for detector measurements (Figure 3a). The space-confinement method was used to synthesize nanoscale phosphors, which were packaged in mini LEDs to evaluate their practical applications (Fig. 3b). It is expected to introduce a new application directly to the domestic LED industry.

Figure 3. Conceptualization of the infrared phosphor with wide emission peaks from blue light-emitting diode excitation.

Source:

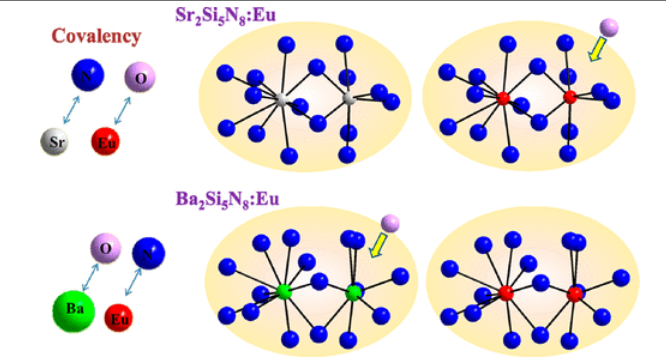

Origin of Thermal Degradation of Sr2–xSi5N8:Eux Phosphors in Air for Light-Emitting Diodes, J. Am. Chem. Soc. 2012, 134, 14108−14117. https://doi.org/10.1021/ja304754b